© 2018-2024 - Macy’s Garage, Ltd.

Macy’s Garage

America’s BEST Triumph Shop

REPRODUCTION PARTS

Birth of a Reproduction Part

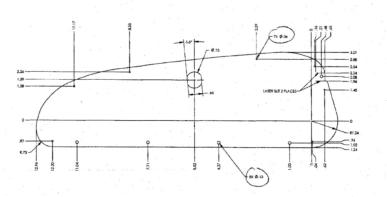

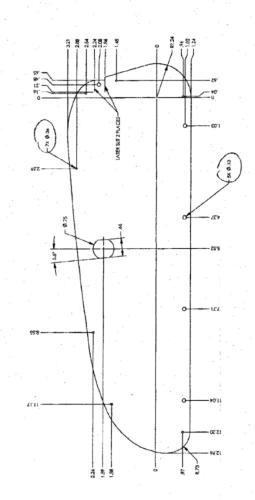

As compared to most vintage auto enthusiasts, we’ve got it pretty easy. A very high percentage of the parts we need to restore our Triumphs and keep them on the road today are readily available. With little more effort than a phone call (or internet order) and a credit card, UPS will deliver a box with shiny new parts to your doorstep in just a few days. This was not always the case, and Triumph owners once had to hunt and dig for parts in much the same way that a DeSoto collector must today. But did you ever stop and think about what it takes to bring just one Triumph part back into production? Original tooling has been lost or destroyed years ago, and most outside suppliers to Standard-Triumph back in the day have ceased to exist. To make any obsolete part available again is a major project requiring lots of time and money. This is the story of what I experienced to produce new cubby box doors and hinges for the TR2-3B models. First, there must be a demand for any part to be reproduced. It must be something that either wears out, or deteriorates with age. In the case of the cubby box door and hinge assembly, both are known to happen. One of my own cars arrived here without an opening cubby box door. An upholstered board was bolted in place to cover the hole, but no hinge or aluminum door was there. Reproductions were not available, and my search for a used one turned up many with broken check rod tabs, rounded out lock holes, and rusted hinges that wouldn’t move. Watching eBay, I found that average used ones were selling at the time in the $40-$50 range, which started me thinking about reproducing them myself. At first glance, these door and hinge assemblies didn’t appear to be anything special. The flat aluminum door was probably stamped originally, but the laser and water jet cutting technologies we have today would make this an easy part to have made. The aluminum rivets that attach the door to the hinge had a striking resemblance to rivets I’d seen on airplanes, so I didn’t anticipate too many problems sourcing these either. The hinge was going to be the hardest component. Originals were chromed steel (which rusted), but I planned to use a non-rusting stainless steel hinge that was highly polished to resemble chrome. I assumed that I could buy long lengths of stainless piano hinge, cut them to length, cut one side a little narrower than the other, add a bend, drill a few holes, have them polished, and ‘presto change-o’, new TR2/3 hinges. And this is the point where the wheels came off of the apple cart! The internet is a wonderful research tool, and by searching for ‘piano hinge’, I was able to learn enough hinge terminology to become dangerous. I learned that the hinge I needed was a 3/32” diameter pin with 1” knuckles (the parts which wrap around the pin), and unequal leaf lengths (where the hinge attaches to the door and the dash). No luck finding pre-made hinges in a useable size, so I went searching for a custom hinge manufacturer to make up a few hundred of these. On more than 30 different occasions I was told that this particular hinge could not be made. The “industry standard” for a 3/32 pin diameter is a ½” knuckle, which would mean twice as many segments on each hinge. I could get hinges with 1” knuckles, but the pin diameter would have to be ¼”, which is a huge increase. Other than those two choices, the required tooling did not exist. Since the knuckles show when the door is closed, both options were unacceptable to me. Not to be discouraged for too long, I surmised that these hinges were originally from England, so perhaps they were operating under a different “industry standard”. Using a number of U.K. search engines, I found several hinge companies in Great Britain, and even a couple who said they could produce the needed type! I quickly shipped samples across the pond and smugly waited for the estimates to come in. WOW! Was I ever in for a shock. All of the cost estimates from the U.K. were well above what anyone would think to be reasonable, and did not include the polishing which was to be done here. The retail cost of a door and hinge was going to be around the century mark, and once again, an unacceptable option. I’d been chasing this for several months by now, and I hated to give up and admit defeat. I just had to find another way! Next stop was to try the orient. Many of our reproduction parts come from that part of the globe, so why should this simple little hinge be any different? Sure enough, I found several places who could make this configuration with no problem. The only question that remained was “how many thousand do you want?” I was beginning to see why this part was not available from any of the usual sources. And then it happened. Out of the blue and by shear luck, I received an e-mail from one of the U.S. companies who’d said “NO” originally. They were kind enough to suggest that I call another company (no web site or e-mail) and speak to “Mr. D”. In what I believed would be my last futile attempt to have these made, I picked up the phone. Yes they had the tooling, send the sample and they would work up a quote on a few hundred hinges. I was surprised again when I received their quote a couple of weeks later. They were going to be affordable! For the first time in about 6 months, I was starting to believe that these parts would become available again! Orders were placed for the aluminum doors and hinges, and the doors were the first to arrive. I wasn’t completely satisfied with the finish on the bare aluminum, so off to the metal polisher they went. When I got them back, I still had to countersink the holes for all of the tiny wood screws used to hold the facings in place. Ten weeks after placing the order, I finally received the hinges. They were perfect copies of the originals, but still had to be polished to look like chrome. Another 6 weeks passed before I got the shiny new hinges back from the polisher, and final assembly could begin at last. Using aircraft cleco fasteners to hold the hinge and door together in the correct orientation, and purchasing a special aircraft rivet squeezer tool, I was finally able to join doors and hinges to create perfect copies of parts which have probably never been available since the original Triumph supplies were exhausted. Ten months had elapsed since I first got the wild idea to make these parts, and they required a huge investment in both time and effort (not to mention $). When I compare my old nasty original samples to the bright, shiny and new reproductions, there’s no doubt in my mind that it was all worth it. Would I do it again? Not for this part. It’s now 2021 and we’re just getting to the bottom of the first order of 300, 12 years after this journey began. During that time, the hinge manufacturer has closed their doors. Sadly, no additional parts will be made. Which brings me to the point where I’ll mention that this market is getting smaller, and manufacturers and suppliers are dropping out of the market (I.E. Victoria British). You should not assume that just because a part is in the catalog today, it will still be available when you decide to buy one a year from now.

© 2018-2024 - Macy’s Garage, Ltd.

Macy’s Garage

America’s BEST Triumph Shop

Birth of a Reproduction Part

As compared to most vintage auto enthusiasts, we’ve got it pretty easy. A very high percentage of the parts we need to restore our Triumphs and keep them on the road today are readily available. With little more effort than a phone call (or internet order) and a credit card, UPS will deliver a box with shiny new parts to your doorstep in just a few days. This was not always the case, and Triumph owners once had to hunt and dig for parts in much the same way that a DeSoto collector must today. But did you ever stop and think about what it takes to bring just one Triumph part back into production? Original tooling has been lost or destroyed years ago, and most outside suppliers to Standard-Triumph back in the day have ceased to exist. To make any obsolete part available again is a major project requiring lots of time and money. This is the story of what I experienced to produce new cubby box doors and hinges for the TR2-3B models. First, there must be a demand for any part to be reproduced. It must be something that either wears out, or deteriorates with age. In the case of the cubby box door and hinge assembly, both are known to happen. One of my own cars arrived here without an opening cubby box door. An upholstered board was bolted in place to cover the hole, but no hinge or aluminum door was there. Reproductions were not available, and my search for a used one turned up many with broken check rod tabs, rounded out lock holes, and rusted hinges that wouldn’t move. Watching eBay, I found that average used ones were selling at the time in the $40-$50 range, which started me thinking about reproducing them myself. At first glance, these door and hinge assemblies didn’t appear to be anything special. The flat aluminum door was probably stamped originally, but the laser and water jet cutting technologies we have today would make this an easy part to have made. The aluminum rivets that attach the door to the hinge had a striking resemblance to rivets I’d seen on airplanes, so I didn’t anticipate too many problems sourcing these either. The hinge was going to be the hardest component. Originals were chromed steel (which rusted), but I planned to use a non-rusting stainless steel hinge that was highly polished to resemble chrome. I assumed that I could buy long lengths of stainless piano hinge, cut them to length, cut one side a little narrower than the other, add a bend, drill a few holes, have them polished, and ‘presto change-o’, new TR2/3 hinges. And this is the point where the wheels came off of the apple cart! The internet is a wonderful research tool, and by searching for ‘piano hinge’, I was able to learn enough hinge terminology to become dangerous. I learned that the hinge I needed was a 3/32” diameter pin with 1” knuckles (the parts which wrap around the pin), and unequal leaf lengths (where the hinge attaches to the door and the dash). No luck finding pre-made hinges in a useable size, so I went searching for a custom hinge manufacturer to make up a few hundred of these. On more than 30 different occasions I was told that this particular hinge could not be made. The “industry standard” for a 3/32 pin diameter is a ½” knuckle, which would mean twice as many segments on each hinge. I could get hinges with 1” knuckles, but the pin diameter would have to be ¼”, which is a huge increase. Other than those two choices, the required tooling did not exist. Since the knuckles show when the door is closed, both options were unacceptable to me. Not to be discouraged for too long, I surmised that these hinges were originally from England, so perhaps they were operating under a different “industry standard”. Using a number of U.K. search engines, I found several hinge companies in Great Britain, and even a couple who said they could produce the needed type! I quickly shipped samples across the pond and smugly waited for the estimates to come in. WOW! Was I ever in for a shock. All of the cost estimates from the U.K. were well above what anyone would think to be reasonable, and did not include the polishing which was to be done here. The retail cost of a door and hinge was going to be around the century mark, and once again, an unacceptable option. I’d been chasing this for several months by now, and I hated to give up and admit defeat. I just had to find another way! Next stop was to try the orient. Many of our reproduction parts come from that part of the globe, so why should this simple little hinge be any different? Sure enough, I found several places who could make this configuration with no problem. The only question that remained was “how many thousand do you want?” I was beginning to see why this part was not available from any of the usual sources. And then it happened. Out of the blue and by shear luck, I received an e-mail from one of the U.S. companies who’d said “NO” originally. They were kind enough to suggest that I call another company (no web site or e- mail) and speak to “Mr. D”. In what I believed would be my last futile attempt to have these made, I picked up the phone. Yes they had the tooling, send the sample and they would work up a quote on a few hundred hinges. I was surprised again when I received their quote a couple of weeks later. They were going to be affordable! For the first time in about 6 months, I was starting to believe that these parts would become available again! Orders were placed for the aluminum doors and hinges, and the doors were the first to arrive. I wasn’t completely satisfied with the finish on the bare aluminum, so off to the metal polisher they went. When I got them back, I still had to countersink the holes for all of the tiny wood screws used to hold the facings in place. Ten weeks after placing the order, I finally received the hinges. They were perfect copies of the originals, but still had to be polished to look like chrome. Another 6 weeks passed before I got the shiny new hinges back from the polisher, and final assembly could begin at last. Using aircraft cleco fasteners to hold the hinge and door together in the correct orientation, and purchasing a special aircraft rivet squeezer tool, I was finally able to join doors and hinges to create perfect copies of parts which have probably never been available since the original Triumph supplies were exhausted. Ten months had elapsed since I first got the wild idea to make these parts, and they required a huge investment in both time and effort (not to mention $). When I compare my old nasty original samples to the bright, shiny and new reproductions, there’s no doubt in my mind that it was all worth it. Would I do it again? Not for this part. It’s now 2021 and we’re just getting to the bottom of the first order of 300, 12 years after this journey began. During that time, the hinge manufacturer has closed their doors. Sadly, no additional parts will be made. Which brings me to the point where I’ll mention that this market is getting smaller, and manufacturers and suppliers are dropping out of the market (I.E. Victoria British). You should not assume that just because a part is in the catalog today, it will still be available when you decide to buy one a year from now.