Macy’s Garage

© 2018-2025 - Macy’s Garage, Ltd.

Blog

WHAT we’re doing, and HOW we’re doing it!

March 29, 2021

All who have ever changed the oil and filter in their 4-cyl TR will know what this is, the oil filter canister and a whole big pile of lower bolt seals. Most of you will not bother to change this seal when changing the filter (unless it is leaking profusely), because the inside canister assembly must be disassembled to change it. And getting the little clip off of the bolt to do so is no easy task! Many will convert to a spin-on type filter, but our experience has been that the spin-on conversions have a better than 50/50 chance of leaking worse than the old canisters would. So imagine our dismay when the supply of these little canister seals seemed to dry up overnight. We’ve had them on back-order since early last summer, and when our own reserves got down to near zero, it was time to stop waiting on the usual suppliers and make something happen all on our own! Following the success we had getting the little fan bolt spacers manufactured overseas (December 21,2020 blog) we began looking again to the far East. It only took 3 weeks from the time we submitted the drawings until we received a small bag with a large number of these critical parts. One major U.S. supplier declined our offer to purchase some of our excess but The Roadster Factory now has them in stock and ready to ship, thanks to our efforts to keep the TR’s rolling (and leaking less). Order from TRF under p/n 500321 (Purolator style).March 22, 2021

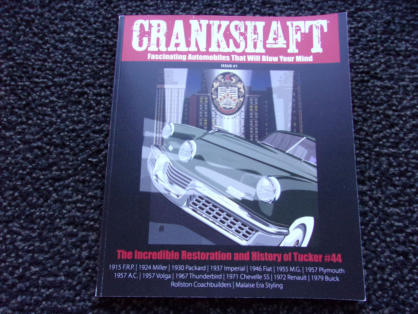

Car guys rejoice, there’s a NEW car magazine in town! Crankshaft magazine has just launched by former Hemmings editor and Triumph junkie Richard Lentinello, and it’s a winner! Issued quarterly in a large 9 x 11 format on 144 high quality pages, it’s more like a coffee table book than the small/thin rags I’m used to. When my sample copy first arrived here at the shop, Tonda had to take it away from me so that I’d get some work done! It’s a real page turner, and I just couldn’t put it down. The photography and stories are all first class, just as I have always expected from Richard’s Hemmings contributions. He’s also brought along several former Hemmings cohorts, so that Crankshaft will benefit from a diversified and experienced staff. Now I have to admit that I’m a “Car Guy” through and through, so I can appreciate the effort and devotion that goes into restoring and maintaining ANY vintage auto. I’m excited to see and read about almost any old car and the history of the industry, so Crankshaft is already my new favorite! Those of you who turn your nose up at anything that’s not a Triumph or a British car might not share my enthusiasm, but with Richard being a life long Triumph Man, you can expect to see our favorite cars creeping in between the covers frequently. As an example of this, Issue #1 has a technical article on crankshafts, and the accompanying photo is….you guessed it, a TR3 crankshaft! I’ve also heard that issue #2 will feature a one-owner TR3B, so we’re off to a great start! For more information, or to order a subscription, visit crankshaftmagazine.com. March 15, 2021 This ‘57 Chevy Sedan Delivery is not a TR, but the story is relevant. I had one of these 50 years ago, and around 2009 I decided that I’d like to have another one. I have a very talented group here who could certainly build this car, but not as efficiently as we can a Triumph TR. We are always busy with client’s TR’s, so the Chevy has sat here untouched for many years now. Since the beginning of 2021, I’ve had two different guys call that were anxious to get their TR’s restored before a serious health issue caught up with them. Sadly, their timeline was not sufficient for us to help them fulfill this one last dream. This made me realize that I’d better get moving if I ever wanted to drive this car, and the sooner I got started, the sooner I’d be able to enjoy it. So I followed my own advice last week and took the car to a specialist that builds several of these Tri-5 Chevys each year. I often tell my guys that we’re in the business of making dreams come true. Perhaps it’s time to let us help you realize your Triumph dream? March 8, 2021 To the untrained eye, and at first glance, this appears to be a “good” TR3 second gear. All of the big teeth are smooth with no nicks or chips, but it’s always the smallest details that matter most. Take a look at the row of tiny teeth above the big ones, and a closer examination shows them to be worn away by nearly ½. These smaller “dog” teeth are what actually complete each gear change when they engage with the synchronizer. When your brass synchro cups (rings) get worn to the point that you hear a small grind when changing gears, it’s these small dog teeth that are slowly being destroyed. If this is happening with your own TR, don’t keep driving it! As this damage and wear gets worse, the transmission will start “jumping” out of the affected gear, on downshifts at first, and then as the wear continues it will also jump out during acceleration. Unfortunately there is no spec to measure how much wear is too much, so absent an owner’s complaint or on a car we can’t test drive, we have to rely on the experienced eye of our gearbox specialist to know when a new gear is required.March 1, 2021

It’s quite common for us to receive engines in crates from TR owners all over the USA and Canada. Gearboxes, overdrives, and rear differentials too! All it takes is a pallet and some basic woodworking skills, and it’s really pretty easy to prepare a large drivetrain component for shipping to have them rebuilt here by the folks with the most knowledge, experience, skills, and special tools. This photo shows a TR3A engine that is headed home to the owner in NY, and just as this one was leaving, another crate arrived here from Seattle. The inbound freight from Seattle (which is just about as far away from us as you can get in the continental USA) was $619 including insurance and lift gate pick-up at the owner’s home. Not cheap, but not as much as you might have imagined either. Return shipping will double this amount, but when compared to the cost of having an engine rebuilt by someone who doesn’t know them as well as we do, and then having to ship it to us later when the first overhaul didn’t work out so well, the shipping cost to send it here and have it done right the first time is quite a bargain!February 22, 2021

We get requests all the time to provide estimates to restore or repair Triumph TRs. The common misconception is that because we work on the same cars over and over again, we should know enough to provide estimates that will resemble the final cost. But here is a perfect example of why that is simply not true. We have installed more TR3 floor pans than anyone else in North America, so you would think that we’d know the time needed within an hour or so either way. But the job is never as routine as simply installing a floor pan, as there will likely be some other rust damage that needs to be repaired before there’s good metal available to weld new floors in. Here you can see that old rusty metal has been replaced from the bottom of the firewall up, and it went as far as to get into the strengthening rib. Sometimes the lower firewall is good, and sometimes it can be repaired below the rib. The patch is more complicated when the rib is bad too, so it takes longer to fabricate it. Same too with the left side kick panel, where repairs extended up over half way into the dimmer switch relief pocket. No two cars ever have the same combination of problems, so our prior experience does nothing to tell us what your car will need, only how to quickly and efficiently repair whatever we find.February 15, 2021

The round black steel rod here (with the paint flaking off), is a TR6 throttle shaft, where it exits the firewall on the left side. This rod is part of the gas pedal, and it runs across the firewall just behind the engine. What’s interesting here is that the small plastic bushing which is supposed to hold the rod as it passes through the firewall (in the middle of the big red “flat washer”) is missing. The opposite end of the rod on the right side of the firewall is also supported by one of these same bushings (also missing on this car), next to the lever where the carburetor linkage is attached. With the passage of time, it’s not uncommon for these bushings to crack and fall out, leaving you with a sloppy gas pedal that won’t fully open the carbs. Many times, when owners bring their cars here with complaints of a “loss of power”, a new set of throttle shaft bushings is all it takes to resolve the problem. But this is the first time we’ve ever seen the battery ground cable used to support the shaft in place of a missing bushing! What will they think of next? Normally, it isn’t a good idea to allow anything near the throttle (or steering) shaft that could snag or prevent unrestricted motion.February 8, 2021

All TR2 and TR3 doors have some amount of wood inside. It’s there to provide a solid base to screw the sidecurtain brackets into, and with the early cars (pre-TS60000) like this door, it also supports the top edge of the door. With these early cars, the wood is held in place with nails, and because they are extremely difficult to pull out of the petrified hardwood, most restorers will simply leave it in place. We strip all of our restorations by chemical dipping, and if we left the wood in place, the chemicals would destroy the wood. They would also leave a residue that would eat through the upper door metal pretty fast too. But even if it weren’t for the stripping complications, this is an area which never received any paint from the factory, as every one we disassemble is bare and highly pitted steel behind the wood. If you strip your car by some other method, it’s still worth the effort to pull the wood and treat the metal behind it as we have done here.February 1, 2021

Hard as I may have tried, I just couldn’t leave this one alone. This is the inside of the heater box from last week’s photo, and not only had the rotting original heater hoses been ignored, but the operational status of the entire heater was never considered during the recent “restoration” either. The mice had made quite a nest in here over the years, and it was completely full of the nesting material. We had started pulling this crap out through one of the air duct ports with a set of mechanical fingers, but it was seemingly never going to end so the heater box had to come out of the car and be opened up to get this remaining amount. Mice urine is highly corrosive, so the heater core was sent to the radiator shop to be cleaned, tested, and repaired before reassembling and reinstalling back into the car. That process also helped to eliminate the nasty odor as well! So now you know why we roll our eyes and bite our tongues whenever someone tells us they have a “fully restored” and “absolutely perfect” Triumph TR, and their car has never been here to our shop before. Sorry, but shiny paint does not a restoration make! The saddest thing is that people will actually pay good money to others for this low tier work, or purchase “restored” cars without truly knowing what they are buying.January 25, 2021

This week’s photo comes from under the dash of a TR6 that’s here in our shop for “just a couple of minor tweaks” as the owner put it. Unfortunately, we often find things like this in cars that have already been “completely restored” by someone else. What it really boils down to is that if the paint is shiny, the car has been “fully restored and better than new” in the mind of the current owner. But what we really have here is lipstick on a pig, as this is just one example of several items that make us believe this car has never received attention in places that are not easily seen. These tiny little twisted heater hoses under the dash are really tough to replace, so we’re not surprised to find original hoses still carrying hot water into the passenger compartment 45-50 years later. But they aren’t going to last forever, and if you’re really lucky they won’t spray hot antifreeze all over your legs (or your wife’s!) and ruin that new carpet set you just installed last year. Restoring any car properly involves more than polishing up the cosmetics, as the functional parts need to be addressed to keep you and your passengers safe, and to make the cars reliable enough to enjoy without worry.January 18, 2021

The lower rear corners on all TR2-TR3A trunk (boot) lids (pre-TS60,000) are notorious for rust, and if not repaired by folks who know why, these corners could be one of the first spots to start bubbling up later and spoil your fresh restoration. Triumph spot welded the inner brace structure to the skin while all parts were bare steel, so there was never a chance to protect this area from moisture and stave off the inevitable rust. We begin all of our restorations by chemically dipping to strip paint, bondo and rust, but chemicals cannot work their way into this hidden area. You can also bet that neither sand nor soda blasting, nor that can of paint stripper you bought at the home center is going to get in there either! Knowing the propensity for these corners to rust, we always go the extra mile and drill the spot welds to separate the brace from the skin. This lets us clean and inspect the rusty metal, and replace any sections that are either completely rusted through or getting close to doing so. While it’s apart, we’ll also treat the hidden metal with a weld-through primer to protect this area from rusting all over again.January 11, 2021

Back on Nov. 16 and Nov. 23 (2020Q4), we showed you a similar view inside a TR3 engine that had “blown” a head gasket 25+ years ago, and subsequently seized up tight after sitting for all these years with water in the #1 cylinder. This is the same engine, 5 weeks later, and the difference is like night and day! We’ll be installing this engine in a TR3A that’s here for a complete frame-up restoration, and I’ll mention that the owners are planning to drive the car home to California when the restoration is complete. This particular TR3A has a lengthy ownership history with the same family, and we are certain that it will continue to serve them well for the next several generations after we’ve worked our magic. There are still plenty of stories to be written about this car and the family members who cherish it, and we are extremely happy to play a big part in the chapter where this fun little car was brought back from the dead and given a new life. If you have a TR that is overdue for some love, perhaps it’s time to give us a call and begin the next chapter of your own Triumph story.January 4, 2021

We’ve been doing a pretty good job of repairing rusted and slightly bent frames here with hastily fabricated jigs and guides to suit each different frame needing attention. But lately we’ve seen an increase in the number of frames that have a problem, so we decided to build a special frame table that would allow us to take precision measurements more quickly for comparison to the factory drawings. The solution was a 975# slab of ¾” thick steel that was flat and true, mounted on top of a rigid steel frame and a set of very expensive locking wheels. We drilled and tapped several strategic locations to accept mounting blocks that would elevate the frame a consistent distance above the surface, with provisions to clamp the frames down securely for repeatable measurements throughout the straightening and rust repair process. The first frame to be repaired on this new table came out perfect, and the body dropped back on like butter!

BLOG

2021-Q1

America’s BEST Triumph Shop

Macy’s Garage

© 2018-2025 - Macy’s Garage, Ltd.

Blog

WHAT we’re doing, and HOW we’re doing it!

March 29, 2021

All who have ever changed the oil and filter in their 4-cyl TR will know what this is, the oil filter canister and a whole big pile of lower bolt seals. Most of you will not bother to change this seal when changing the filter (unless it is leaking profusely), because the inside canister assembly must be disassembled to change it. And getting the little clip off of the bolt to do so is no easy task! Many will convert to a spin-on type filter, but our experience has been that the spin-on conversions have a better than 50/50 chance of leaking worse than the old canisters would. So imagine our dismay when the supply of these little canister seals seemed to dry up overnight. We’ve had them on back-order since early last summer, and when our own reserves got down to near zero, it was time to stop waiting on the usual suppliers and make something happen all on our own! Following the success we had getting the little fan bolt spacers manufactured overseas (December 21,2020 blog) we began looking again to the far East. It only took 3 weeks from the time we submitted the drawings until we received a small bag with a large number of these critical parts. One major U.S. supplier declined our offer to purchase some of our excess but The Roadster Factory now has them in stock and ready to ship, thanks to our efforts to keep the TR’s rolling (and leaking less). Order from TRF under p/n 500321 (Purolator style).March 22, 2021

Car guys rejoice, there’s a NEW car magazine in town! Crankshaft magazine has just launched by former Hemmings editor and Triumph junkie Richard Lentinello, and it’s a winner! Issued quarterly in a large 9 x 11 format on 144 high quality pages, it’s more like a coffee table book than the small/thin rags I’m used to. When my sample copy first arrived here at the shop, Tonda had to take it away from me so that I’d get some work done! It’s a real page turner, and I just couldn’t put it down. The photography and stories are all first class, just as I have always expected from Richard’s Hemmings contributions. He’s also brought along several former Hemmings cohorts, so that Crankshaft will benefit from a diversified and experienced staff. Now I have to admit that I’m a “Car Guy” through and through, so I can appreciate the effort and devotion that goes into restoring and maintaining ANY vintage auto. I’m excited to see and read about almost any old car and the history of the industry, so Crankshaft is already my new favorite! Those of you who turn your nose up at anything that’s not a Triumph or a British car might not share my enthusiasm, but with Richard being a life long Triumph Man, you can expect to see our favorite cars creeping in between the covers frequently. As an example of this, Issue #1 has a technical article on crankshafts, and the accompanying photo is….you guessed it, a TR3 crankshaft! I’ve also heard that issue #2 will feature a one-owner TR3B, so we’re off to a great start! For more information, or to order a subscription, visit crankshaftmagazine.com.March 15, 2021

This ‘57 Chevy Sedan Delivery is not a TR, but the story is relevant. I had one of these 50 years ago, and around 2009 I decided that I’d like to have another one. I have a very talented group here who could certainly build this car, but not as efficiently as we can a Triumph TR. We are always busy with client’s TR’s, so the Chevy has sat here untouched for many years now. Since the beginning of 2021, I’ve had two different guys call that were anxious to get their TR’s restored before a serious health issue caught up with them. Sadly, their timeline was not sufficient for us to help them fulfill this one last dream. This made me realize that I’d better get moving if I ever wanted to drive this car, and the sooner I got started, the sooner I’d be able to enjoy it. So I followed my own advice last week and took the car to a specialist that builds several of these Tri-5 Chevys each year. I often tell my guys that we’re in the business of making dreams come true. Perhaps it’s time to let us help you realize your Triumph dream?March 8, 2021

To the untrained eye, and at first glance, this appears to be a “good” TR3 second gear. All of the big teeth are smooth with no nicks or chips, but it’s always the smallest details that matter most. Take a look at the row of tiny teeth above the big ones, and a closer examination shows them to be worn away by nearly half. These smaller “dog” teeth are what actually complete each gear change when they engage with the synchronizer. When your brass synchro cups (rings) get worn to the point that you hear a small grind when changing gears, it’s these small dog teeth that are slowly being destroyed. If this is happening with your own TR, don’t keep driving it! As this damage and wear gets worse, the transmission with start “jumping” out of the affected gear, on downshifts at first, and then as the wear continues it will also jump out during acceleration. Unfortunately there is no spec to measure how much wear is too much, so absent an owner’s complaint or on a car we can’t test drive, we have to rely on the experienced eye of our gearbox specialist to know when a new gear is required.March 1, 2021

It’s quite common for us to receive engines in crates from TR owners all over the USA and Canada. Gearboxes, overdrives, and rear differentials too! All it takes is a pallet and some basic woodworking skills, and it’s really pretty easy to prepare a large drivetrain component for shipping to have them rebuilt here by the folks with the most knowledge, experience, skills, and special tools. This photo shows a TR3A engine that is headed home to the owner in NY, and just as this one was leaving, another crate arrived here from Seattle. The inbound freight from Seattle (which is just about as far away from us as you can get in the continental USA) was $619 including insurance and lift gate pick-up at the owner’s home. Not cheap, but not as much as you might have imagined either. Return shipping will double this amount, but when compared to the cost of having an engine rebuilt by someone who doesn’t know them as well as we do, and then having to ship it to us later when the first overhaul didn’t work out so well, the shipping cost to send it here and have it done right the first time is quite a bargain!February 22, 2021

We get requests all the time to provide estimates to restore or repair Triumph TRs. The common misconception is that because we work on the same cars over and over again, we should know enough to provide estimates that will resemble the final cost. But here is a perfect example of why that is simply not true. We have installed more TR3 floor pans than anyone else in North America, so you would think that we’d know the time needed within an hour or so either way. But the job is never as routine as simply installing a floor pan, as there will likely be some other rust damage that needs to be repaired before there’s good metal available to weld new floors in. Here you can see that old rusty metal has been replaced from the bottom of the firewall up, and it went as far as to get into the strengthening rib. Sometimes the lower firewall is good, and sometimes it can be repaired below the rib. The patch is more complicated when the rib is bad too, so it takes longer to fabricate it. Same too with the left side kick panel, where repairs extended up over half way into the dimmer switch relief pocket. No two cars ever have the same combination of problems, so our prior experience does nothing to tell us what your car will need, only how to quickly and efficiently repair whatever we find.February 15, 2021

The round black steel rod here (with the paint flaking off), is a TR6 throttle shaft, where it exits the firewall on the left side. This rod is part of the gas pedal, and it runs across the firewall just behind the engine. What’s interesting here is that the small plastic bushing which is supposed to hold the rod as it passes through the firewall (in the middle of the big red “flat washer”) is missing. The opposite end of the rod on the right side of the firewall is also supported by one of these same bushings (also missing on this car), next to the lever where the carburetor linkage is attached. With the passage of time, it’s not uncommon for these bushings to crack and fall out, leaving you with a sloppy gas pedal that won’t fully open the carbs. Many times, when owners bring their cars here with complaints of a “loss of power”, a new set of throttle shaft bushings is all it takes to resolve the problem. But this is the first time we’ve ever seen the battery ground cable used to support the shaft in place of a missing bushing! What will they think of next? Normally, it isn’t a good idea to allow anything near the throttle (or steering) shaft that could snag or prevent unrestricted motion.February 8, 2021

All TR2 and TR3 doors have some amount of wood inside. It’s there to provide a solid base to screw the sidecurtain brackets into, and with the early cars (pre-TS60000) like this door, it also supports the top edge of the door. With these early cars, the wood is held in place with nails, and because they are extremely difficult to pull out of the petrified hardwood, most restorers will simply leave it in place. We strip all of our restorations by chemical dipping, and if we left the wood in place, the chemicals would destroy the wood. They would also leave a residue that would eat through the upper door metal pretty fast too. But even if it weren’t for the stripping complications, this is an area which never received any paint from the factory, as every one we disassemble is bare and highly pitted steel behind the wood. If you strip your car by some other method, it’s still worth the effort to pull the wood and treat the metal behind it as we have done here.February 1, 2021

Hard as I may have tried, I just couldn’t leave this one alone. This is the inside of the heater box from last week’s photo, and not only had the rotting original heater hoses been ignored, but the operational status of the entire heater was never considered during the recent “restoration” either. The mice had made quite a nest in here over the years, and it was completely full of the nesting material. We had started pulling this crap out through one of the air duct ports with a set of mechanical fingers, but it was seemingly never going to end so the heater box had to come out of the car and be opened up to get this remaining amount. Mice urine is highly corrosive, so the heater core was sent to the radiator shop to be cleaned, tested, and repaired before reassembling and reinstalling back into the car. That process also helped to eliminate the nasty odor as well! So now you know why we roll our eyes and bite our tongues whenever someone tells us they have a “fully restored” and “absolutely perfect” Triumph TR, and their car has never been here to our shop before. Sorry, but shiny paint does not a restoration make! The saddest thing is that people will actually pay good money to others for this low tier work, or purchase “restored” cars without truly knowing what they are buying.January 25, 2021

This week’s photo comes from under the dash of a TR6 that’s here in our shop for “just a couple of minor tweaks” as the owner put it. Unfortunately, we often find things like this in cars that have already been “completely restored” by someone else. What it really boils down to is that if the paint is shiny, the car has been “fully restored and better than new” in the mind of the current owner. But what we really have here is lipstick on a pig, as this is just one example of several items that make us believe this car has never received attention in places that are not easily seen. These tiny little twisted heater hoses under the dash are really tough to replace, so we’re not surprised to find original hoses still carrying hot water into the passenger compartment 45-50 years later. But they aren’t going to last forever, and if you’re really lucky they won’t spray hot antifreeze all over your legs (or your wife’s!) and ruin that new carpet set you just installed last year. Restoring any car properly involves more than polishing up the cosmetics, as the functional parts need to be addressed to keep you and your passengers safe, and to make the cars reliable enough to enjoy without worry.January 18, 2021

The lower rear corners on all TR2-TR3A trunk (boot) lids (pre-TS60,000) are notorious for rust, and if not repaired by folks who know why, these corners could be one of the first spots to start bubbling up later and spoil your fresh restoration. Triumph spot welded the inner brace structure to the skin while all parts were bare steel, so there was never a chance to protect this area from moisture and stave off the inevitable rust. We begin all of our restorations by chemically dipping to strip paint, bondo and rust, but chemicals cannot work their way into this hidden area. You can also bet that neither sand nor soda blasting, nor that can of paint stripper you bought at the home center is going to get in there either! Knowing the propensity for these corners to rust, we always go the extra mile and drill the spot welds to separate the brace from the skin. This lets us clean and inspect the rusty metal, and replace any sections that are either completely rusted through or getting close to doing so. While it’s apart, we’ll also treat the hidden metal with a weld-through primer to protect this area from rusting all over again.January 11, 2021

Back on Nov. 16 and Nov. 23 (2020Q4), we showed you a similar view inside a TR3 engine that had “blown” a head gasket 25+ years ago, and subsequently seized up tight after sitting for all these years with water in the #1 cylinder. This is the same engine, 5 weeks later, and the difference is like night and day! We’ll be installing this engine in a TR3A that’s here for a complete frame-up restoration, and I’ll mention that the owners are planning to drive the car home to California when the restoration is complete. This particular TR3A has a lengthy ownership history with the same family, and we are certain that it will continue to serve them well for the next several generations after we’ve worked our magic. There are still plenty of stories to be written about this car and the family members who cherish it, and we are extremely happy to play a big part in the chapter where this fun little car was brought back from the dead and given a new life. If you have a TR that is overdue for some love, perhaps it’s time to give us a call and begin the next chapter of your own Triumph story.January 4, 2021

We’ve been doing a pretty good job of repairing rusted and slightly bent frames here with hastily fabricated jigs and guides to suit each different frame needing attention. But lately we’ve seen an increase in the number of frames that have a problem, so we decided to build a special frame table that would allow us to take precision measurements more quickly for comparison to the factory drawings. The solution was a 975# slab of ¾” thick steel that was flat and true, mounted on top of a rigid steel frame and a set of very expensive locking wheels. We drilled and tapped several strategic locations to accept mounting blocks that would elevate the frame a consistent distance above the surface, with provisions to clamp the frames down securely for repeatable measurements throughout the straightening and rust repair process. The first frame to be repaired on this new table came out perfect, and the body dropped back on like butter!

America’s BEST Triumph Shop