© 2018-2025 - Macy’s Garage, Ltd.

Macy’s Garage

CAMSHAFT DEGREE

Degree your Camshaft

Just exactly what does it mean to “Degree” a camshaft, and why is it important? To answer the “what” part of this question first, you have to first understand that the camshaft (which controls the opening and closing of the engine valves) is “timed” to the rotation of the crankshaft and the position of the pistons so that the engine can run. Engine designers can change the performance characteristics of an engine by varying the timing of when a valve opens and closes in relation to the piston in each cylinder, and many of today’s modern engines feature variable camshaft or valve timing to change an engine’s efficiency and power while running over a wide range of operating conditions. Unfortunately, in older design engines like our Triumphs, the timing of the camshaft is fixed at where it was installed, but we can assure that the camshaft is opening and closing the valves precisely as designed through the degree-ing procedure. When installing a camshaft on most older engines, all one has to do to get the timing correct is to line up the marks on the timing gears, and install the timing chain. But due to variations in manufacturing tolerances, the reference marks on a new (or old) camshaft or gears may be off by a few degrees, and the performance characteristics of the engine will change. Racers have been degree-ing their camshafts for decades, both to assure the camshaft is operating the valves at the precise times it should be, and to change the valve timing in search of a bit more speed. How much variation makes a difference? As little as one degree of crankshaft rotation! Okay, so that’s fine for the racer guys, but I drive my Triumph on the street so why should I care if my camshaft timing is perfect or not? That’s because the Standard-Triumph engineers did not see fit to include reference marks on the timing gears, and included extra holes in the camshaft gear so that you (or whomever had your engine apart last) only have a 1-in-4 chance of getting it right! If every part is machined perfectly and you select the wrong side of the cam gear or the wrong pair of bolt holes, your camshaft timing could be off one-quarter, one-half, or three-quarters of a tooth in either direction (advanced ahead of the crankshaft or retarded behind the crank). In case you’re wondering, one quarter of a tooth on the cam gear of a TR 4 cylinder engine equals 4.28 degrees of crankshaft rotation, and that will have a huge effect on how well your engine runs. Advancing a camshaft will move the power range to the low RPM side and retarding the camshaft will move the power ranger to higher RPM’s. Of course, these are small movements, and advancing or retarding a camshaft too far in either direction will result in an engine that won’t run at all, and could possibly damage pistons and valves just by cranking the starter! Yes, the factory workshop manual does mention a procedure for checking the camshaft timing, but it’s anything but precise because it’s based upon an imprecise method for finding the top dead center of pistons #1 and #4, and requires repositioning the camshaft sprocket without moving anything else. It also only works for a stock Standard-Triumph camshaft, and is worthless if you want to make a performance upgrade through an aftermarket camshaft design. We recognized the shortcomings of the factory method long ago, and developed our own tools and procedures to degree a cam that will allow greater precision in every instance. Be sure to read the captions with every photo to see how it’s done here at America’s BEST Triumph shop!

The first tool you'll need is a Degree Wheel and an adjustable pointer.

The large graduations make it easy to see the exact position of the

crankshaft when valves open and close, and you can then compare

these numbers to the camshaft specs.

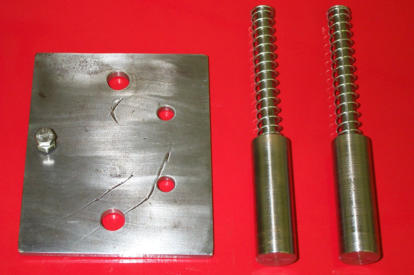

We made this plate and "dummy" tappets to take all of our measurements from.

The springs are needed to keep the dummy tappets pushed down on the

camshaft for precise readings. The bolt and lock nut on the left side of the plate

are to stop the piston when locating piston TDC.

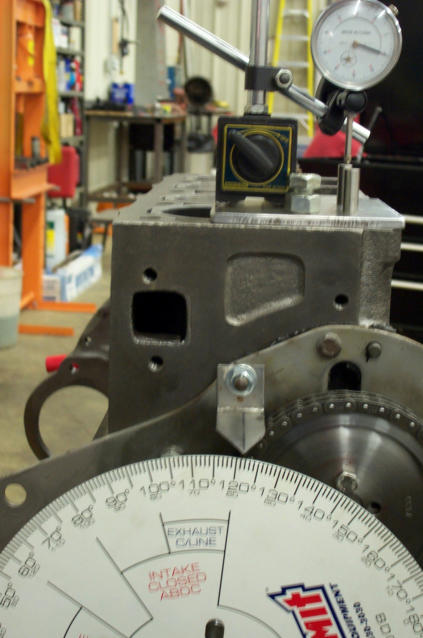

The dummy tappets and springs are placed in the lifter bores, then the plate is secured

to a pair of head bolt stud holes. Run the piston stop bolt down to where it will stop the

piston 10-15 degrees before TDC. Rotate the crankshaft in both directions and stop the

piston on either side of TDC. Read the markings on the degree wheel, add together and

divide by 2. Now re-set the pointer to locate the precise TDC. This is necessary

because there is approximately 3 degrees crankshaft rotation where the piston will not

move at TDC. Loosen and remove the piston stop bolt to allow complete crankshaft

rotation. Look at the ports in the head if you need to determine which dummy tappet is

intake and which is exhaust!

Using a magnetic base that's locked onto our top plate, we can take readings from the top of the dummy tappets with a dial indicator to determine

precisely when the intake and exhaust valves will open and close. Read the degrees of crankshaft rotation off of the large degree wheel, and compare to

the camshaft specs. Adjust your camshaft gear and timing chain and measure again. Given the 4.28 degree adjustment on the TR camshaft sprocket and

the varying tolerances of the camshaft manufacturer, you may not be able to achieve a racer's precision, but you should be able to get within a degree

and a half in most cases. If you have to compromise, remember that an advanced cam (valves opening and closing earlier than spec) will add power to

the low end of the RPM range, which is preferable for a street engine.

America’s BEST Triumph Shop

© 2018-2025 - Macy’s Garage, Ltd.

Macy’s Garage

America’s BEST Triumph Shop

Degree your Camshaft

Just exactly what does it mean to “Degree” a camshaft, and why is it important? To answer the “what” part of this question first, you have to first understand that the camshaft (which controls the opening and closing of the engine valves) is “timed” to the rotation of the crankshaft and the position of the pistons so that the engine can run. Engine designers can change the performance characteristics of an engine by varying the timing of when a valve opens and closes in relation to the piston in each cylinder, and many of today’s modern engines feature variable camshaft or valve timing to change an engine’s efficiency and power while running over a wide range of operating conditions. Unfortunately, in older design engines like our Triumphs, the timing of the camshaft is fixed at where it was installed, but we can assure that the camshaft is opening and closing the valves precisely as designed through the degree-ing procedure. When installing a camshaft on most older engines, all one has to do to get the timing correct is to line up the marks on the timing gears, and install the timing chain. But due to variations in manufacturing tolerances, the reference marks on a new (or old) camshaft or gears may be off by a few degrees, and the performance characteristics of the engine will change. Racers have been degree-ing their camshafts for decades, both to assure the camshaft is operating the valves at the precise times it should be, and to change the valve timing in search of a bit more speed. How much variation makes a difference? As little as one degree of crankshaft rotation! Okay, so that’s fine for the racer guys, but I drive my Triumph on the street so why should I care if my camshaft timing is perfect or not? That’s because the Standard-Triumph engineers did not see fit to include reference marks on the timing gears, and included extra holes in the camshaft gear so that you (or whomever had your engine apart last) only have a 1-in-4 chance of getting it right! If every part is machined perfectly and you select the wrong side of the cam gear or the wrong pair of bolt holes, your camshaft timing could be off one-quarter, one-half, or three-quarters of a tooth in either direction (advanced ahead of the crankshaft or retarded behind the crank). In case you’re wondering, one quarter of a tooth on the cam gear of a TR 4 cylinder engine equals 4.28 degrees of crankshaft rotation, and that will have a huge effect on how well your engine runs. Advancing a camshaft will move the power range to the low RPM side and retarding the camshaft will move the power ranger to higher RPM’s. Of course, these are small movements, and advancing or retarding a camshaft too far in either direction will result in an engine that won’t run at all, and could possibly damage pistons and valves just by cranking the starter! Yes, the factory workshop manual does mention a procedure for checking the camshaft timing, but it’s anything but precise because it’s based upon an imprecise method for finding the top dead center of pistons #1 and #4, and requires repositioning the camshaft sprocket without moving anything else. It also only works for a stock Standard-Triumph camshaft, and is worthless if you want to make a performance upgrade through an aftermarket camshaft design. We recognized the shortcomings of the factory method long ago, and developed our own tools and procedures to degree a cam that will allow greater precision in every instance. Be sure to read the captions with every photo to see how it’s done here at America’s BEST Triumph shop! The first tool you'll need is a Degree Wheel and an adjustable pointer. The large graduations make it easy to see the exact position of the crankshaft when valves open and close, and you can then compare these numbers to the camshaft specs. We made this plate and "dummy" tappets to take all of our measurements from. The springs are needed to keep the dummy tappets pushed down on the camshaft for precise readings. The bolt and lock nut on the left side of the plate are to stop the piston when locating piston TDC. The dummy tappets and springs are placed in the lifter bores, then the plate is secured to a pair of head bolt stud holes. Run the piston stop bolt down to where it will stop the piston 10-15 degrees before TDC. Rotate the crankshaft in both directions and stop the piston on either side of TDC. Read the markings on the degree wheel, add together and divide by 2. Now re-set the pointer to locate the precise TDC. This is necessary because there is approximately 3 degrees crankshaft rotation where the piston will not move at TDC. Loosen and remove the piston stop bolt to allow complete crankshaft rotation. Look at the ports in the head if you need to determine which dummy tappet is intake and which is exhaust! Using a magnetic base that's locked onto our top plate, we can take readings from the top of the dummy tappets with a dial indicator to determine precisely when the intake and exhaust valves will open and close. Read the degrees of crankshaft rotation off of the large degree wheel, and compare to the camshaft specs. Adjust your camshaft gear and timing chain and measure again. Given the 4.28 degree adjustment on the TR camshaft sprocket and the varying tolerances of the camshaft manufacturer, you may not be able to achieve a racer's precision, but you should be able to get within a degree and a half in most cases. If you have to compromise, remember that an advanced cam (valves opening and closing earlier than spec) will add power to the low end of the RPM range, which is preferable for a street engine.